MEP Plans in Construction

Why do we exactly need MEP plans? Forget plans; why do we even need MEP? Building design has come a long way from random idea attempts to a more intelligent drawing format that is comprehensible to each stakeholder. The biggest change that has arrived with this modern era in how we design our buildings is the increasing machine complexities in our buildings.

Now our buildings are more like big machines, i.e., made of systems traditionally labeled as building systems. And the estimation of growth in community and working spaces would propel this trend further. The problems are so complex that you need machines to solve them.

In another way, we could term these building systems as MEPF systems. To efficiently execute tasks like movement, power supply, water resource circulation, and firefighting, we need these. And to assemble all these, the requirement is for MEP plans.

You Would like Read –

- What Are The Benefits Of Using Revit Mep?

- Bim For Mep Designers : An Ultimate Guide

What are MEP plans?

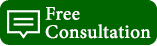

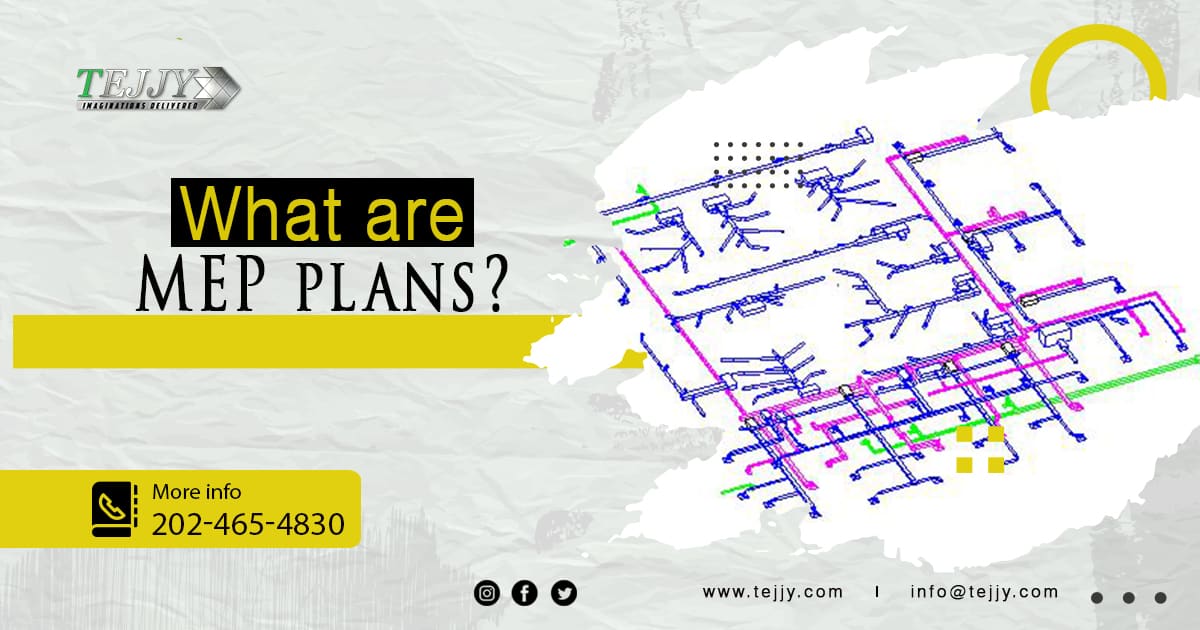

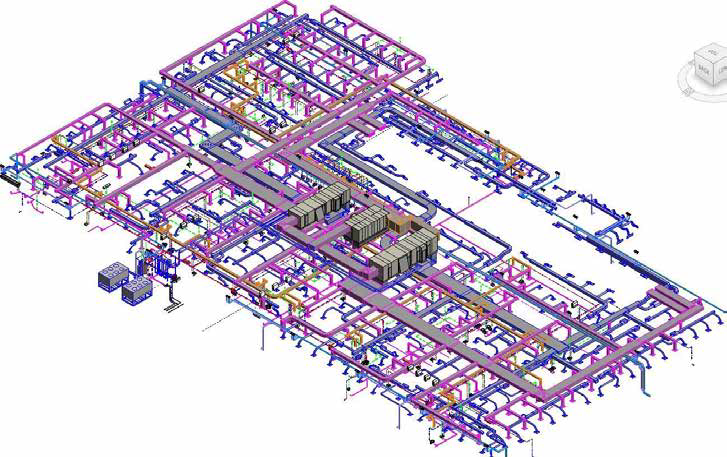

MEP plans are a 2D planar top view of building systems, i.e., visible electrical equipment, components and fixtures in the structure, mechanical ducting, plumbing mains, and important terminals. Conventionally, a plan is a 2D planar top view but if we take the word “plan” from a scheme sense then, there is a concept of 3D MEPF plans too. The case of 3D MEPF plans is it’s about isometric views and 3D zoom-ins for MEPF systems.

MEP plans detail the installation and operation of building systems, including the location, materials, and layout of pipes, ducts, and conduits. They also outline connections to other parts, energy efficiency measures like insulation and air sealing, and maintenance and repair guidelines for the systems.

An MEP plan shows all of the visible electrical equipment, components, and fixtures in the structure, including mechanical ducting, plumbing mains, and important terminals.

Understanding Each Component in Depth

Mechanical

The mechanical system inside a building could be divided into two to three categories. Generally, mechanical systems refer to HVAC, elevators, and escalators. One additional category could be mechanical support behind water supply across the infrastructure.

Mechanical drawings are crucial for any construction project, including HVAC (heating, ventilation, and air conditioning) and MEP (mechanical, electrical, and plumbing). They accurately identify geometric features of the machine component and include orthographic views, also known as orthogonal projections or multiview drawings.

Mechanical drawings typically include:

- A cover sheet with legends

- Notes and details

- Title blocks

- A bill of materials

- Break lines

- Continuous lines, center lines, and hidden lines.

- They specify the design and modifications of:

- Mechanical systems

- Ductwork dimensions

- Damper locations

- Design air delivery rates.

- Thermostat locations

- Diffuser locations

- Supplemental cooling systems.

Electrical

The electric system is basically the power backend of your building. Each component in the electric system of your building is responsible for the distribution of power and the work being assisted by the power supply.

Electrical drawings are crucial for communication, troubleshooting, and documenting information about power systems on construction sites. They help ensure that power systems run safely, efficiently, and smoothly, and they can also identify potential risks that can be nipped in the bud before they become a problem.

Key elements of effective electrical drawings include:

- Standardized symbols for electrical components

- Wiring representations

- Layers and dimensions.

These elements help engineers understand the layout and troubleshoot issues, saving time and costs by avoiding problems, delays, and unnecessary purchases.

Electrical systems, categorized into low-voltage and high-voltage, are crucial for lighting and small appliances.

In detail, electrical plans may include:

- Connections of fixtures and components

- Main cable

- Wire runs

- Wiring diagrams

- Schedules

- Main switches and fused switches

- Tiebreakers

- Power transformers

- Winding connections

- Power lines

- Interconnection of electrical wires,

Equipment such as batteries, generators, air conditioning, and solar panels. Legends provide symbols, abbreviations, and descriptions, while wall lines are usually drawn lighter than fixtures.

Designing them with safety and energy efficiency in mind is essential. Proper grounding, circuit protection devices, and surge protection are essential.

To make relevant and accurate electrical drawings, consider using the interior layout as a bedrock, doing a walkthrough, planning for additional outlets, considering furniture placement, and using varied lighting.

By doing so, you can catch errors that may have been missed and place outlets and switches in the best locations. Additionally, consider the client’s preferences for lighting, such as task lighting, accent lighting, or ambient lighting, to ensure a well-lit space.

Plumbing

The plumbing system of a building is responsible for circulating water for inhabitants’ usage and removing residual wastewater outside the building premises for treatment.

A well-planned plumbing plan is crucial for any remodeling project involving significant plumbing work.

A plumbing plan illustrates the system that will bring water in and take waste back out, including –

- Water supply lines

- Drains

- Vent pipes

- Valves

- Fixtures like toilets and sinks

Using official plumbing symbols and color codes, a plumbing plan helps save time and expenses, enables better thinking through the job, and minimizes extra trips to the plumbing supply store.

To create a plumbing plan, draw all fixtures to scale, mark drain lines and vents, make riser drawings, indicate pipe sizes and the exact type of every fitting, mark locations for valves, and specify the type of valve.

Inclusion of key coding, drain-waste-vent (DWV) elevation, supply drawing, and supply drawing is a must. The DWV elevation describes the system that will carry water, waste, and air out of the house, while the supply drawing indicates the estimated length of supply pipes and pipe size.

Refer to the plumbing plan when making your shopping list of materials to ensure the correct sizes and lengths are purchased.

The purpose of MEP plans

As our building requirements are getting complexier, the address to MEP designs are must! The office culture gives rise to buildings that facilitate business as well as a hefty workforce, just as the institutional and recreational buildings have a large footfall.

The felicitation of basic services such as water, power, and ventilation now requires a mechanical approach, and MEP systems are a product of this. That is why MEP design is inevitable in today’s time. MEP design initiates with MEP planning, and it is all about designers and engineers coming together to devise MEP plans.

An optimized MEP plan ensures MEP plans are crucial for building projects as they provide a comprehensive overview of the systems used to power, heat, cool, and ventilate a building.

- They analyze the building’s size, climate, and activities, ensuring efficient systems that don’t waste energy.

- A well-detailed MEP plan leads to increased cost savings by prioritizing energy efficiency and resource optimization.

- They also act as a guideline to maintain buildings in good condition through proactive maintenance checks and inspections.

Quality assurance is ensured through guidelines and detailed drawings, ensuring that all components are installed correctly and that potential safety hazards are identified and mitigated.

Current trends with MEP designing and planning

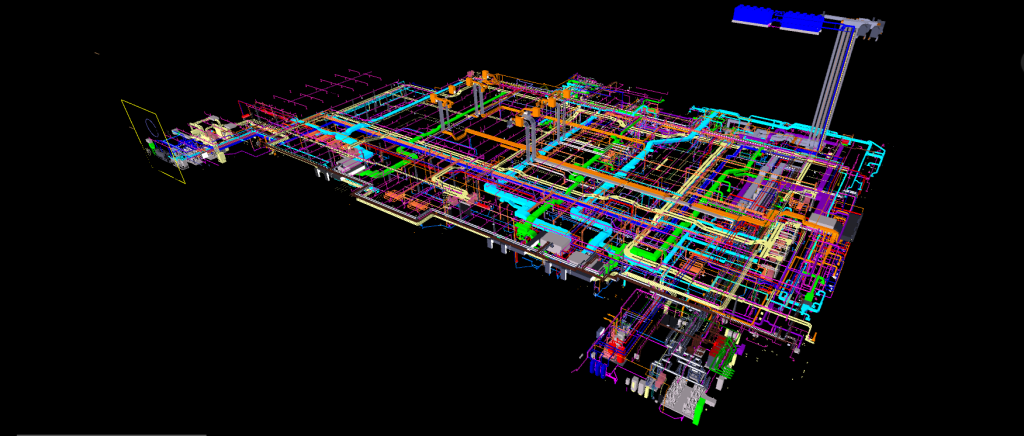

The future of MEPF design and construction is promising, with the continued adoption of building information modeling (BIM) and the growing use of artificial intelligence (AI) in the industry.

Prefabrication, a process that involves off-site manufacturing of building components, is expected to become more common in the future.

Renewable energy is becoming increasingly important in the construction industry, and designers and constructors will need to be familiar with the latest technologies to design and construct sustainable buildings.

The demand for energy-efficient, water-efficient, and environmentally friendly buildings is growing, and MEPF designers and constructors must design and construct energy-efficient, water-efficient, and environmentally friendly buildings.

The latest trends in MEPF BIM include cloud-based BIM, augmented reality, virtual reality, 4D BIM, 5D BIM, integrated data management, smart building technologies, and sustainability.

As technology continues to evolve, more innovative developments in MEPF design and planning services are expected.

Why Choose Tejjy for MEP Design Plans?

The route to choosing the right vendor could be challenging; it is almost equivalent to finding a needle in an ocean of sand. However, to make it simpler, there is a way out. Prioritize a vendor who prioritizes technology.

We can say this comfortably as we have more than 500 MEP projects and we outsource our projects to sub-vendors too. And when we say it, we mean it; technology is the differentiator. At Tejjy, we follow the following

Centralized MEP data management

We utilize a centralized digital platform for MEP plan storage, including drawings, documents, and maintenance records. Implement version control mechanisms for accurate information and stakeholder collaboration.

Laser Scanning for Accurate MEP Plan Drafting

3D laser scanning captures detailed as-built conditions of structures for precise MEP plans, while point cloud integration in BIM software enhances the representation of existing conditions.

Concurrent Approach Considering Various Critical Parameters

We emphasize the importance of collaborative workflows and parametric design in MEP projects, promoting real-time adjustments and analysis based on changing requirements or conditions.

BIM Dimensioning for MEP Planning

Our MEP plan outputs are routed through a thorough BIM dimension approach. The inevitable parameters like cost, time, assets, sustainability, and more must be followed to ensure optimal planning.

You would like to explore our services