Design-build and design-bid-build are two common construction delivery methods, dictating stakeholder interactions. Choosing the right method impacts the contractor’s profit margin, timeline, and project quality. Project owners must consider expertise, risk tolerance, and project size to determine the best method. This article discusses their advantages and disadvantages. But before that, let us understand the elements of project delivery methods.

Design

An architect is usually to produce construction drawings that will be put out to bid. To transform the owner’s vision into a thorough document, the architect works collaboration with engineering experts too. Post documentation of drawings, they are subject to through revision for optimizing their positioning in the bidding process.

Bid (or tender)

General contractors make bids on design documents following their discussions with other project stakeholders the project. The final document outlines duties, makes scope clear, and accounts for labor and material costs. Project owners can choose the best bid as per their requirements to move forward to execution.

Build

Additionally, a general contractor oversees the project’s construction from inception to end. A preset order is often followed when working. The general contractor sets a certain scope of work, and modifications to the design cannot be made at this late stage.

What is design bid build?

The design-bid-build methodology is a traditional project delivery method used in the construction industry. It involves three stages: the design phase, the bidding/tender phase, and the construction phase. Architects collaborate with owners, structural engineers, MEPs, and civil engineers to create schematic designs, prepare construction drawings, and bid documents.

General contractors then involve subcontractors in bidding on subcomponents. The construction phase involves executing the entire design and ensuring permit approval.

Understanding the Design-Bid-Build Process

The design-bid-build process is a linear approach where the project design and construction are awarded separately and sequentially. This method has been the traditional approach in the construction industry for many years.

Role Separation in Design-Bid-Build

In design-bid-build, there’s a clear separation of roles:

- Owner: Manages separate contracts with designers and contractors

- Architect/Engineer: Responsible for the complete design

- General Contractor: Selected through bidding process to execute the construction

- Subcontractors: Hired by the general contractor for specialized work

Phases of a Design-Bid-Build Project

A design-bid-build project typically follows these phases:

- Design Phase (by architect/engineer)

- Bidding Phase (contractors submit bids based on completed design)

- Construction Phase (winning bidder executes the project)

This method offers the owner more control over the design process but can lead to longer project timelines and potential conflicts between design and construction teams.

What is Design-Build Service in Construction Management?

The design-build service in construction management, also known as integrated project delivery, involves a design-builder contracting a project divided into architect-led and contractor-led designs and collaborating with subcontractors and consultants to deliver quality, timely, and cost-effective projects.

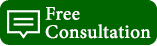

Design Build vs Design Bid Build Pros and Cons

The key pros and cons between the two methodologies would help you decide and choose the best method construction technique for your project.

Comparing Design-Build vs Design-Bid-Build

When choosing between design-build and design-bid-build, it’s crucial to understand their differences in various aspects:

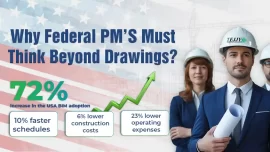

Project Timeline Differences

Design-build typically offers faster project completion:

- Design-build projects showed a 9% difference in total project duration and a 13% difference in construction phase duration compared to design-bid-build projects, with design-build projects being shorter.

- The overlapping of design and construction phases in design-build contributes to this time efficiency.

Cost Implications

Cost considerations vary between the two methods:

- Design-build projects experienced fewer change orders than comparable design-bid-build projects, but the average cost per change order was greater for design-build projects.

- The dollar value of claims per project was significantly lower for design-build projects than for comparable design-bid-build projects.

Risk Distribution

Risk allocation differs significantly:

- In design-build, the design-builder assumes more risk, potentially leading to higher initial costs but fewer change orders and claims.

- Design-bid-build distributes risk among multiple parties, which can lead to more disputes but may offer more competitive initial pricing.

Design build Methodology is less risky

Building design and construction are performed by a single team, reducing risk and promoting teamwork. While a lack of involvement from the builder in the design-bid-build process can lead to miscommunication and issues later in the project, affecting overall project quality and causing delays.

Design build yields faster results

The design and construction teams collaborate to achieve a common goal, ensuring seamless construction. However, delays can occur due to appointment intervals and finger-pointing in the design-bid-build methodology, leading to project stoppages or extra time for completion.

Design build is Budget-friendlier

The design-build method of construction is simpler and more cost-effective due to the coordination between the designer and contractor. On the other hand, design bid build often leads to increased complications during project execution, including design and documentation issues, resulting in higher project costs.

Design build is all about involving non-technical stakeholders

Design bid-build and design-build both require owner input, but design bid-build offers more control and flexibility, allowing for changes at any time during the project. Also, the design-build approach comes with interference from non-technical stakeholders, which may not be that beneficial for project economics.

Design bid build has design orientation and project clarity

Design-build firms create 3D models for building owners but lack personalized designs. The Design Bid Build method ensures project completion within a specific timeline, avoiding overlapping phases and improving project clarity with design specifications.

Design bid build case study

Osceola County in Florida faced significant challenges in delivering a large-scale design and construction program funded by impact fees. The initial traditional design-bid-build approach resulted in delays, budget overruns, and numerous change orders. In 2007, a new administration adopted an innovative Construction Manager at Risk (CMR) program to expedite the delivery of 11 major roadway projects with 13 bridges.

Key project details:

- Delivery Method: Construction Manager/General Contractor (CM/GC) with a focus on the CMR program.

- Procurement Method: Qualifications-Based Selection for six CMs chosen through requests for proposals (RFPs).

- Total Project Cost: $350 million program covering 11 projects and 13 bridges.

- Funding Source: 100% locally funded through impact fees.

- Construction Schedule: The goal was to have eleven major roadway projects under construction within the first year.

Innovative Approaches:

CMR Program: Osceola County opted for a CMR program, differing from traditional CM/GC by prohibiting the CM from self-performing any work.

Qualifications-Based Selection: Six CMs were selected based on qualifications, with the work divided among them according to their strengths.

Continuous Collaboration: Weekly meetings between CMs and designers allowed real-time review of plans, enhancing efficiency in construction drawings and maintenance of traffic (MOT).

Guaranteed Maximum Price (GMP): Mini GMPs were utilized, pricing each early work package. Projects were built in phases, accelerating construction and reducing costs.

Local Economic Boost: Approximately 90% of construction dollars were distributed to local contractors, stimulating the local economy.

Results and Benefits:

- Within the first year, all 11 major roadway projects were ready for construction, achieving a production rate 55 times higher than the previous five years.

- $105 million in savings (23% reduction) attributed to innovations from the CM/GC process.

- 9 out of every 10 construction dollars were allocated to local contractors, providing economic benefits during a challenging period.

- The use of CM/GC successfully advanced stagnant projects that struggled under the traditional design-bid-build methodology.

Considerations:

- Environmental, Right-of-Way, and Utility: CMs are actively involved in planning and design to minimize impacts. Projects are built in “mini” phases to accelerate progress.

- Risk Management: Risks are shared among the owner, designer, and construction manager. Budgeting for overruns was emphasized instead of relying on errors and omission claims.

- Owner Management/Quality Assurance: A Construction Engineering Inspection (CEI) firm involved in plan reviews and development to ensure constructability. CM managed general contractors, while CEI ensured quality.

- Stakeholder Communication: Extensive training by the Osceola County administration to educate design firms and the contracting community about the benefits of CM/GC. CM is responsible for communication with the affected community.

Overall, the use of CM/GC proved to be a successful and innovative approach, overcoming previous challenges and delivering projects efficiently and cost-effectively.

Design-build case study

Project Overview: The Pentagon Renovation Program (PenRen) was a complex renovation initiative aimed at preserving the historic Pentagon structure while modernizing it to meet future needs. Initiated in 1992, the project faced serious budget and schedule challenges six years into its execution.

Challenges and Turning Point: As Wedge 1 of the Pentagon was near completion, the devastating terrorist attack on September 11, 2001, significantly damaged the Pentagon. This event led to the birth of the Phoenix Project, a response initiative with the ambitious goal of rebuilding the damaged area before the one-year anniversary of the attack.

Response and Achievements:

- The Phoenix Project adopted a design-build contract approach, allowing for a nimble response to the urgent reconstruction needs.

- Completed 28 days before the one-year anniversary of the attack, the Phoenix Project was not only swift but also remarkably cost-effective, finishing $194 million under budget.

- The design-build contract’s flexibility and efficiency played a crucial role in accelerating the schedule by four years, overcoming a challenge that would have been nearly impossible with traditional construction methods.

Key Project Participants:

- Client/Owner: Pentagon Renovation Program

- Design-Builder: Hensel Phelps Construction Co.

- Engineers: Tadjer Cohen and Edelson, Timmons Group, Wedlinger and Associates Inc., Schrimer Engineering

- Specialty Consultants: Heller and Metzger, Culinary Advisors

- Specialty Contractors: M.C. Dean Inc., Southland Industries, National Fire Protection

- Other Team Members: Sterling Construction Services Inc., P&P Contractors, Jewell Industries, LVI Environmental Services Inc., Roman Mosaic and Tile Company, Physical Securities, Custom Walls and Windows Inc.

Project Outcome and Recognition:

- Despite the challenges, PenRen was successfully completed after ten years, meeting its design mandate and preserving the Pentagon’s historic significance while anticipating future needs.

- The project received the prestigious Best Overall Project award at the 2011 National Design-Build Awards, acknowledging its resilience, innovation, and successful execution in the face of unprecedented adversity.

Future of project delivery

The Design-Build Institute of America (DBIA) claims Design-Build is the most efficient delivery method, accounting for half of construction expenditures in 2021. Growing adoption of Design-Build methodology in construction projects could potentially increase its acceptance and application across all American regions. And technologies like VDC and BIM is further accelerating this notion of every project stakeholder collaborating real time.

The Future of Design-Build and Design-Bid-Build

The construction industry is evolving, with significant implications for project delivery methods:

Emerging Trends in Construction Project Delivery

- By 2025, design-build is expected to account for $400 billion worth of work in the U.S.

- Design-build will account for 47% of U.S. construction spending in 11 key non-residential market segments by 2025, up from 42% in the five-year period ending in 2020.

- Design-bid-build’s share of construction spending will fall to 15% by 2025, down from 23% currently.

Technological Advancements Influencing Delivery Methods

- Building Information Modeling (BIM) and Virtual Design and Construction (VDC) are enhancing collaboration in both design-build and design-bid-build projects.

- Cloud-based project management tools are improving communication and efficiency across all delivery methods.

- Prefabrication and modular construction techniques are becoming more prevalent, potentially favoring the integrated approach of design-build.

These trends suggest a continued shift towards more collaborative and integrated project delivery methods, with design-build gaining prominence. However, design-bid-build will likely remain relevant for certain project types and in regions where regulatory frameworks favor traditional approaches.

Financial and Temporal Dynamics

Understanding the financial and temporal aspects of both methods is crucial for project success:

Cost Efficiency Comparison

- Half of all survey respondents reported that design-build exceeded project expectations, and three out of four characterized design-build experiences as good or excellent.

- Between 2018 and 2021, collective design-build CPiP spending was expected to increase 18%, from $274 billion to $324 billion.

- While design-build often results in lower overall costs, initial bids may be higher due to the increased risk assumed by the design-builder.

Accelerating Construction Timelines

- Design-build projects showed a 9% difference in total project duration and a 13% difference in construction phase duration compared to design-bid-build projects, with design-build projects being shorter.

- The overlapping of design and construction phases in design-build contributes significantly to faster project completion.

These dynamics highlight the potential for design-build to offer both cost and time savings, particularly for complex or time-sensitive projects.

Tejjy’s design-build approach

Design-build is a popular alternative to traditional design-bid-build construction delivery, offering reduced risk and control.

However, it may not be suitable for all situations, and not all stakeholders agree. Design-build can compress schedules significantly, with some large infrastructure projects completed within five years. Success depends on trust and collaboration within the design-build team, which can reduce change orders and improve the project. Clear organization, accessibility of information, and open communication are essential for project success.

Further Reading