Digital Twin Services

Bridging the Gap between Physical and Digital World for Smarter Management

Online digital twin facilitates detailed information of any space in 3D environment. We streamline the work process, from site familiarization and taking measurements to remotely assessing and surveying for facility management. Tejjy Inc. Provides tailored digital twin solutions for construction, infrastructure, manufacturing, and facility management with latest 3D laser scanning technology and BIM Integration.

Tejjy utilizes digital twin from scanning or digital twin for facility management to create actionable insights for smarter operations. We monitor and optimize everything from predictive maintenance to lifecycle management to reduce costs and improve sustainability.

What is Digital Twin Technology?

The physical asset is scanned using the latest scanning technology. The real-time scanned data captured has detailed geometrical and structural information of the asset. The real-time scanned data captured has detailed geometrical and structural information of the asset. BIM integration into point cloud data creates a 3D digital model of physical asset. Creating a collaborative world where Digital twins are connected digital replicas of physical assets.

For facility management, leak detections, and infrastructural sector real-time behavioral data is captured from IoT sensors to virtually replicate the state of the physical assets. Digital twins in construction are virtual representation of built environment with existing conditions for stakeholders to have 3D virtual tours even in critical building intelligence. It is achieved by syncing the data twins with their tangible counterparts via as-built surveying data, laser scanning and point cloud data, BIM software, and other IoT sensors. These “living” rendered models offer stakeholders a centralized source of access with specialized software like Trimble Connect, Quadri, Agile Assets, etc.

Tejjy's digital twin for facilities and properties management

Scan-to-BIM automation

BIM- IoT operational data management

Facility and property coordination

Digital Twin Updation

Benefit of Digital Twin Technology For Government Infrastructure Projects

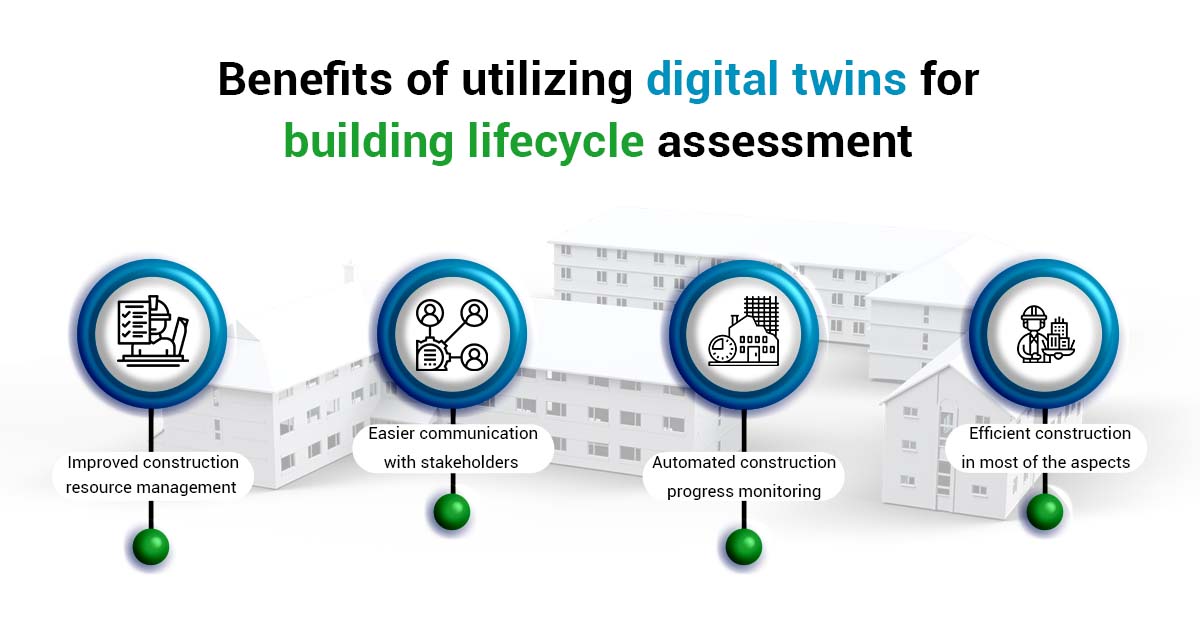

The integration of digital twin technology and 3D laser scanning is transforming the management and operation of government buildings. These technologies enhance efficiency, sustainability, and decision-making processes in public infrastructure. Digital twining services for architecture and construction provides a crucial advantage of improving analytical potential of BIM (Building Information Modeling). Digital twinning for facility management allows facility owners and managers to digitally experiment on the replica and analyze the outcomes before the actual execution. Some of the benefits of digitization of construction facility are:

Enhanced Planning and Design:

Detailed 3D visualization through digital model helps stakeholders to visualize projects before they are built. This facilitates design validation, error detection, and conflict resolution during the planning phase

Accurate As-Built Documentation

This technology provides precise as built of a building’s layout, including architectural and structural elements. It ensures that renovations or expansions are seamlessly integrated with existing structures

Operational Efficiency

Digital twins are proactive tools, allowing stakeholders to identify operational inefficiencies, contributing to faster project delivery time and hence reduced lifecycle operational costs.

Stakeholders Collaboration

The data from 3D scans can be transformed into BIM models, which enhance collaboration among architects, engineers, and contractors. This integration allows for better project coordination and reduces the likelihood of costly errors during construction

Sustainability Initiatives:

The Federal government can adopt sustainable development by monitoring energy efficiency, reducing carbon footprint, and better resource management. Reduced carbon footprint, better resource management. Modeling for urban planning, leads to more informed decisions regarding zoning and transportation.

Predictive Maintenance

Using the real-time site monitoring and the data analytics digital twinning services for facility management enables enhanced predictive maintenance by foreseeing equipment failures, minimizing downtime, etc.

Industries Adopting Digital Twin

Manufacturing Sector – Optimizing and streamlining production process.

Manufacturing Sector – Optimizing and streamlining production process.  Construction and Architecture Industry – Site and construction monitoring and simulating building performance.

Construction and Architecture Industry – Site and construction monitoring and simulating building performance.  Healthcare Sector- Patient monitoring and healthcare facility management.

Healthcare Sector- Patient monitoring and healthcare facility management.  Smart Cities –Urban Planning and resource optimization.

Smart Cities –Urban Planning and resource optimization.

Energy and Utilities –Predictive maintenance for power plants and managing renewable energy sources.

Energy and Utilities –Predictive maintenance for power plants and managing renewable energy sources.  Aerospace –Monitoring aircraft performances and improving fuel efficiency.

Aerospace –Monitoring aircraft performances and improving fuel efficiency.  Defense Sector- Creating training simulation for military personnel.

Defense Sector- Creating training simulation for military personnel.  Infrastructure Sector- Bridges, Roads, highways for infrastructural management and maintenance.

Infrastructure Sector- Bridges, Roads, highways for infrastructural management and maintenance.

Why choose Tejjy Inc?

With 18+ years of experience in VDC BIM integrated 3D laser scanning for AEC is affordable and yet quality-driven 8(a) certified company

End-to-End service:

- Tejjy with our proficient workforce, offers a comprehensive solution to your construction facility digitization needs.

- Our digital solution includes all the digital twin functions right from consultation, design, implementation to maintenance and monitoring of real time data.

Industry Expertise:

- Being a leading AEC solution provider, we deliver customer centric services with 100% satisfaction.

- Our experience spans across the entire project lifecycle including as-built services, laser scanning services, BIM services, digital twin updation, etc.

Seamless Solution Integration:

- Tejjy brings established expertise in 3D Laser scanning, BIM and Digitization services

- Our proficiencies in facility management, as-built services, Scan to BIM services can be leveraged into an all-encompassing integrated solution.

Digitize your assets, optimize your future with 3D Laser Scanning and Digital Twins